measuring zinc plating thickness|zinc plating thickness chart : purchasers Coating thickness measurement/Dry film thickness measurement is used to determine the thickness of coatings on components and to monitor the coating process. Our measuring instruments solve a wide range of applications in . web26 de ago. de 2023 · Welcome to the GSM-Forum forums. You are currently viewing our boards as a guest which gives you limited access to view most discussions and access .

{plog:ftitle_list}

Resultado da Sinopse: Ao despertar no Mundo Espiritual, André Luiz se depara com criaturas assustadoras e sombrias vivendo, juntamente com ele, neste lugar escuro e sombrio. Além disso, ele também se assusta por perceber que apesar de ter "morrido" ele ainda continua vivo e ainda sente fome, sede, .

Coating thickness is tested by using a magnetic thickness gauge. There are three types of magnetic thickness gauges: pencil-style, banana-style, and electronic. Electronic thickness gauges are the most common and the most accurate.thickness (Figure 2) of each zinc coating varies. This practical aid examines the .

Coating thickness measurement/Dry film thickness measurement is used to determine the thickness of coatings on components and to monitor the coating process. Our measuring instruments solve a wide range of applications in .The thickness of zinc plating that you should use depends on the environment that the component is in. We have produced some recommendations based on what we find is suitable for most of our customers. The corrosion resistance of the zinc depends on two things:Coating Thickness vs. Coating Weight. The service life of zinc coatings is a linear function of the zinc coating thickness. However, zinc coating thickness alone can be deceiving when evaluating zinc applied by different processes. .

An electroless nickel coating is uniform; it will not build up on corners or projections. The deposited metal layer has an even thickness over all surfaces of the component regardless of its shape; this cannot be achieved with electrodeposited coatings. Typical thickness of electroless plating can be as thin as .0005" and up to.010".AN034 Measuring the copper thickness in plated through-holes on PCBs 0.57 MB AN044 Determining the thickness of thermally sprayed aluminium (TSA) coatings on stainless steel 1.66 MB AN047 Measuring the zinc plating on nails with PHASCOPE® PMP10 0.52 MB AN091 Different ways to achieve valid measurement values and optimize measurement .

When measuring the thickness of zinc plating on steel using a magnetic induction gauge, can I calibrate zero on steel provided with gauge or do I need to attempt to remove zinc coating from a part to use as zero? Bennett Bergquist - .

Measure the thickness of zinc coatings ; Analyze the microstructure of the coating and the base material ; . The resulting coating usually has a thickness between 7-15 µm, but can be as thick as 20 μm. After fabrication, some hot dip galvanized parts may be given further treatment, including heat treatment or static immersion into a molten . E.g. - if base metal thickness is 0.22 mm x width 850 mm x 681000 mm and zinc coating including both sides is 40 gsm/sq meter? And how does the zinc thickness and consumption change with change in thickness? I zinc coating gets changed to 25 gsm/sq meter and 80 gsm/sq meter? Manish Jain self employed - Mumbai, Maharashtra, India April 11, 2022

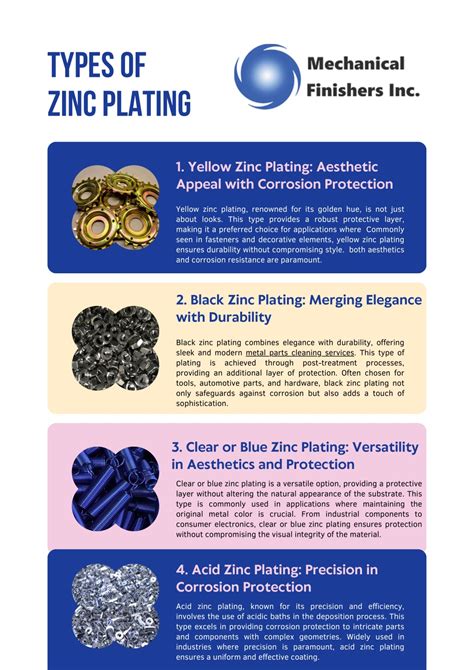

zinc plating types

Gas Permeability Test System distribution

The PosiTector 6000 is a rugged, fully electronic coating thickness gauges use magnetic and eddy current principles to measure coating thickness on ALL metals, accurately and quickly . The PosiTector 6000 FNDS coating thickness gage measures individual thicknesses of both paint and zinc layers in a duplex coating system simultaneously. Eddy current coating thickness gages (e.g. PosiTector 6000 N Series) look and operate like electronic magnetic gages. They are used to measure paint and coating thickness over all nonferrous metals. Like magnetic electronic gages, they commonly use a constant pressure probe and display results on an LCD.

An electroless nickel coating is uniform; it will not build up on corners or projections. The deposited metal layer has an even thickness over all surfaces of the component regardless of its shape; this cannot be achieved with electrodeposited coatings. Typical thickness of electroless plating can be as thin as .0005" and up to.010".Our Metallurgy lab uses the following instruments to measure plating thickness. . Zinc Plate Thickness ; Zinc Plating Thickness ; In states where Applied Technical Services, LLC does not provide engineering services, engineering services will be provided by ATS Engineering, (P)LLC or a licensed contractor. .An electroless nickel coating is uniform; it will not build up on corners or projections. The deposited metal layer has an even thickness over all surfaces of the component regardless of its shape; this cannot be achieved with electrodeposited coatings. Typical thickness of electroless plating can be as thin as .0005" and up to.010".

Contact the GalvInfo Center The usual criterion for determining the expected service life of zinc coatings is thickness: the thicker the coating, the longer the service life. Hot-dip galvanizing (batch or continuous), electrogalvanizing, zinc plating 1.7 mils (43µm) Zinc Spraying (metallizing) 1.9. What are the XRF testing requirements for plating zinc nickel alloy? A. X-ray fluorescence (XRF) is a common technique used for quality control of zinc and zinc nickel alloy plating deposits. Accurate thickness .

Gas Permeability Test System distributing

SGS MSi can perform plating thickness using SEM and Optical Microscopy (Image Analysis) on material as thin as .25 microns (.000010 in. or 10 micro-inches). Each examination is traceable to NIST Standard 484. . ASTM A90, . The plating thickness measurement is an important part of the electroplating process quality inspection and an important guarantee for the quality of the electroplating products. In order to control the plating . For thickness measurement tests , a minimum of five widely dispersed measurements are taken over the surface area of the specimen in order to represent the average specimen coating thickness. In order to test coating thickness of products whose surface area is greater than 160 in 2 (1032 cm 2 ),.Ultrasonic coating thickness gages (e.g. PosiTector 200) emit a high frequency sound pulse that travels into the coating via a coupling gel and reflects from ANY surface that is different in density.Paint thickness readings are obtained by measuring the time taken for the ultrasonic signal to propagate from the probe to the coating/substrate interface and back.

ASTM B633 Plating Specifications. About ASTM Plating Specifications. The American Society for Testing and Materials (ASTM) develops technical standards in manufacturing that have been adopted by various industries to enhance performance, safety and ensure higher-quality products.. ASTM specifications are among the most common standards used for Zinc and . In order to enable coating thickness measurement to be carried out on the basis of the phase measurement, frequencies of more than 10 MHz are required-these cannot be achieved in typical coating thickness instruments. . The repeatability precision of the zinc thickness measurement is as low as a few tens of nanometers, and that of the paint .

Electrical wiring: zinc and nickel coatings are replacing older cadmium coatings How XRF measures coatings The Vanta handheld XRF analyzer can measure coating thickness from 0.00 to approximately 60.00 microns, depending on the material. X-rays are emitted from the analyzer, and they strike the sample, causing it to fluoresce.The PosiTector 6000 FNDS duplex coating thickness gage measures the individual thicknesses of both the paint and the zinc layers in a duplex coating system with a single reading. In Duplex mode, the PosiTector 6000 FNDS utilizes both magnetic (ferrous) and eddy current (non-ferrous) principles simultaneously to calculate and display the individual paint and zinc layer thicknesses. So for zinc plating at 100% efficiency the formula would be: "Thickness of plating in microns = 0.285 * A/sq/dm * minutes of plating time" We might estimate the efficiency of alkaline zinc plating at 77%, and therefore multiply the 0.285 x .77 and arrive at "Thickness of plating in microns = 0.22 * A/sq/dm * minutes of plating time" :-)

Plating, the process of covering a substrate with a thin layer of metal, plays an essential role in modern manufacturing and materials science. The thickness of the plating layer is a critical parameter that can significantly impact the finished product’s performance, durability, and aesthetic qualities. In industries where precision is non-negotiable, such as aerospace, .Measuring zinc plating thickness of fasteners 22 June 2021 By the global applications team at Helmut Fischer headquarters Nails and other fasteners are coated to protect them against rust; the thickness of the zinc layer corresponds directly to how long they can resist corrosion.ISO 2064, Metallic and other inorganic coatings — Definitions and conventions concerning the measurement of thickness ISO 8044:2015, Corrosion of metals and alloys — Basic terms and definitions . The zinc coating system to be used should be selected by taking the following items into account: a) the general environment (macro-climate) in .

zinc plating thickness standard

Gas Permeability Test System agent

25 de ago. de 2023 · Foi assim com a aluna de direito Ana Elisa Souza, 23 anos, que abandonou um estágio no ano passado para encarar o OnlyFans. Postou ali vídeos eróticos sozinha e com o namorado, que foram parar .

measuring zinc plating thickness|zinc plating thickness chart